Uaʻike nuiʻia keʻano o ka maikaʻi o ka carbide saw blades e pili pono ana i ka maikaʻi o nā huahana i hoʻoponoponoʻia.

Ua pilikia paha ʻoe i ke koho ʻana! A laila e ʻoluʻolu e heluhelu i kēia ʻatikala me ka hoʻomanawanui, manaʻo wau e hiki ke kōkua hou iā ʻoe.

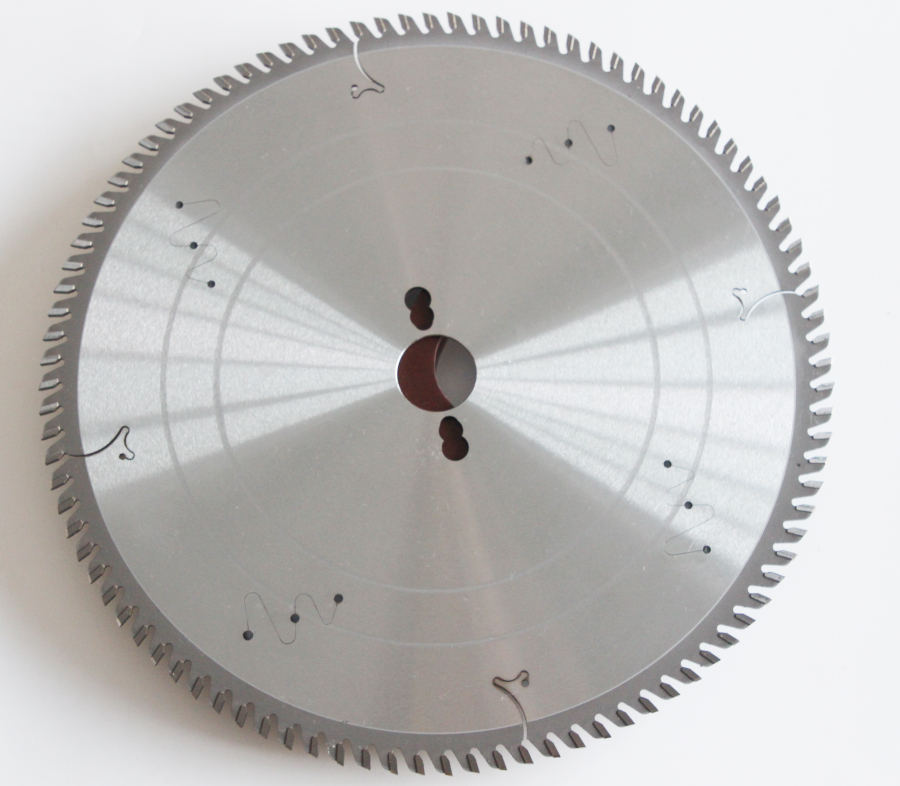

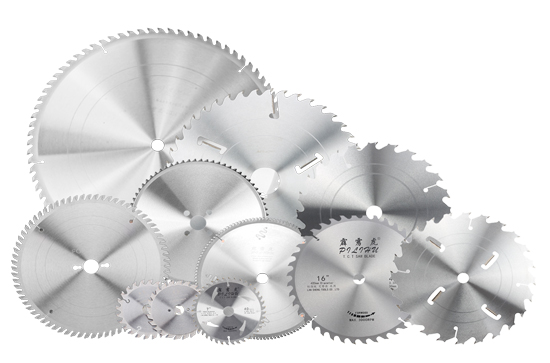

Loaʻa i nā lau ʻike Carbide nā ʻāpana like ʻole e like me ke ʻano o ke poʻo ʻokiʻoki alloy, ka mea o ka substrate, ke anawaena, ka helu o nā niho, ka mānoanoa, ka ʻaoʻao niho, ke kihi, a me ka aperture. Hoʻoholo kēia mau ʻāpana i ka hiki ke hana a me ka hana ʻoki ʻana o ka ʻili. No laila, i ke koho ʻana i ka ʻili ʻili, pono e koho pololei i ke ʻano o nā mea ʻili, ka mānoanoa, ka wikiwiki o ka ʻili, ke kuhikuhi o ka ʻili, ka wikiwiki hānai, a me ka laulā o ke ala ʻili.

ʻO ka mea mua, ke koho ʻana i nā ʻano carbide cemented.

ʻO nā ʻano mea maʻamau o ka carbide cemented he tungsten-cobalt a me tungsten-titanium. No ka mea ʻoi aku ka maikaʻi o ka hopena o ka carbide cemented tungsten-cobalt, ʻoi aku ka nui o ka hoʻohana ʻana i ka ʻoihana hana lāʻau. Ke piʻi aʻe ka ʻike cobalt, e piʻi ka paʻakikī a me ka ikaika flexural o ka alloy, akā e emi ana ka paʻakikī a me ke kūpaʻa. E koho e like me ke kūlana maoli.

ʻO ka lua, ke koho o ka substrate.

1. 65Mn puna kila i maikai elasticity a me ka plasticity, waiwai waiwai, maikai wela wela hardenability, haʻahaʻa wela wela, oluolu deformation, a hiki ke hoʻohana 'ia no ka ike maka e koi haahaa oki koi.

2. ʻO ke kila kila kila he kiʻekiʻe carbon maʻiʻo a me ka thermal conductivity kiʻekiʻe, akā hāʻule nui kona paʻakikī a me ke kūpaʻa ʻana i ka wā e ʻike ʻia ai i kahi mahana o 200 ℃-250 ℃, nui ka deformation mālama wela, ʻilihune ka paʻakikī, a maʻalahi ka manawa hoʻonā. e pohā. Hana i nā mea waiwai no nā mea hana.

3. Ke hoʻohālikelike ʻia me ke kila mea hana kalapona, ʻoi aku ka maikaʻi o ka pale ʻana i ka wela, ke kūpaʻa ʻaʻahu a me ka hana ʻoi aku ka maikaʻi. ʻO ka mahana deformation wela he 300 ℃ - 400 ℃, kūpono ia no ka hana ʻana i nā ʻōpala circular saw kiʻekiʻe.

4. High-wikiwiki mea paahana kila i maikai hardenability, ikaika paakiki a rigidity, a emi wela-pale deformation. He kila ikaika loa ia me ka thermoplasticity kūpaʻa a kūpono ia no ka hana ʻana i nā ʻili ʻili kiʻekiʻe kiʻekiʻe.

ʻO ke kolu, ke koho o ke anawaena.

ʻO ke anawaena o ka ʻili ʻili e pili ana i nā mea ʻili i hoʻohana ʻia a me ka mānoanoa o ka mea hana ʻili. He liʻiliʻi ke anawaena o ka ʻili maka, a he haʻahaʻa ka wikiwiki o ka ʻoki ʻana; ʻoi aku ka kiʻekiʻe o ke anawaena nui o ka ʻili ʻili ma ka ʻili a me nā lako ʻeli, a ʻoi aku ka kiʻekiʻe o ka pono ʻeli. Ua koho ʻia ke anawaena o waho o ka ʻili ʻili e like me nā ʻano hoʻohālike like ʻole.

ʻO ka hā, ke koho ʻana i ka helu o nā niho.

ʻO ka mea maʻamau, ʻoi aku ka nui o ka nui o nā niho, ʻoi aku ka nui o ka ʻoki ʻana i hiki ke ʻoki ʻia i ka manawa hoʻokahi, ʻoi aku ka maikaʻi o ka ʻoki ʻana, akā ʻoi aku ka nui o ka ʻoki ʻana i nā niho e pono e hoʻohana i ka carbide cemented, ʻoi aku ka kiʻekiʻe o ke kumukūʻai o ka ʻili, akā. ʻOi aku ka liʻiliʻi o nā niho, ʻoi aku ka liʻiliʻi o ka puʻupuʻu ma waena o nā niho, kahi maʻalahi e wela ai ka ʻili; Eia kekahi, nui loa nā niho ʻike. Ke hoʻohālikelike ʻole ka nui o ka hānai, liʻiliʻi ka nui o ka ʻoki ʻana o kēlā me kēia niho, kahi e hoʻonui ai i ka friction ma waena o ka ʻoki ʻoki a me ka mea hana, a pili i ke ola lawelawe o ka ʻoki ʻoki. ʻO ka maʻamau ka 15-25mm ka spacing niho, a pono ke koho ʻia kahi helu kūpono o nā niho e like me ka mea e ʻoki ʻia.

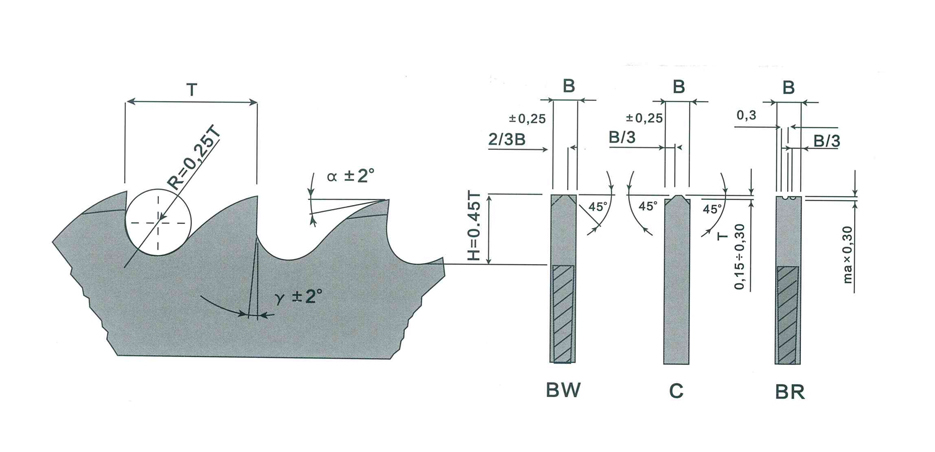

ʻO ka lima, ʻo ke koho ʻana i ka ʻike niho.

1. ʻO nā niho hema a me ka'ākau ka mea i hoʻohana nuiʻia, wikiwiki ka wikiwiki o kaʻokiʻana, a maʻalahi ka wili. He kūpono ia no ka ʻoki ʻana a me ka ʻeli ʻana i nā ʻano lāʻau paʻa paʻa a palupalu a me nā papa paʻa, nā papa multi-layer, nā papa ʻāpana, a me nā mea ʻē aʻe. ʻoki ʻana i nā ʻano papa like ʻole me nā kumu lāʻau; Hoʻohana pinepine ʻia ka niho hema a me ka ʻākau me ke kihi rake maikaʻi ʻole no ka hoʻopili ʻana ma muli o ko lākou mau niho ʻoi a me ka maikaʻi ʻokiʻoki maikaʻi, kūpono i nā panela.

2. He oolea ka pahi ike niho palahalaha, lohi ka mama o ka oki ana, a o ka wili ana ka mea maalahi. Hoʻohana nui ʻia no ka ʻeli ʻana i ka lāʻau maʻamau, me ke kumu kūʻai haʻahaʻa. Hoʻohana nui ʻia ia no nā lau ʻike alumini me nā anawaena liʻiliʻi e hōʻemi i ka hoʻopili ʻana i ka wā e ʻoki ai, a i ʻole no ka ʻoki ʻana i nā lau ʻike e hoʻopaʻa i ka lalo o ke awāwa.

3. ʻO nā niho palahalaha o ke alapiʻi he hui ia o nā niho trapezoidal a me nā niho palahalaha. ʻOi aku ka paʻakikī o ka wili. Hiki iā ia ke hōʻemi i ka haki ʻana o ka veneer i ka wā ʻeli. He kūpono ia no ka ʻeli ʻana i nā panela lāʻau hoʻokahi a me nā papa ʻelua veneer a me nā papa ahi. I mea e pale ai i ka hoʻopili ʻana, hoʻohana pinepine nā ʻili alumini i nā ʻili ʻili me ka nui o nā niho o nā niho pālahalaha.

4. Hoʻohana pinepine ʻia nā niho alapiʻi hoʻohuli ʻia ma ka maka o ka ʻike ʻaoʻao lalo o ka ʻike panel. I ka ʻike ʻana i ka papa lāʻau ʻelua maka, hoʻoponopono ka ʻike slot i ka mānoanoa e hoʻopiha ai i ka grooving o ka ʻili lalo, a laila hoʻopau ka ʻili nui i ke kaʻina ʻili o ka papa. Kāohi i ka ʻoki ʻana i ka ʻaoʻao ma ka ʻaoʻao saw.

Ka manawa hoʻouna: ʻOkakopa-11-2021